Sectors > Rail

Helping Transport for London keep the lights on

Coupling modular lighting units with an innovative energy storage system, MARL created an ultra-reliable lighting system for a fleet of London Underground trains.

The client

Transport for London (TfL) is responsible for London’s expansive public transport network. The agency oversees the London Underground rail network, which accommodates a staggering 1.35 billion users annually.

Each year, more than 110 million passengers make use of the historic Bakerloo line. Its 72TS trains have been in operation since the early 1970s. TfL tasked MARL with upgrading the 72TS resulting in a demonstrated 50% energy saving, enabling TfL to install further passenger focused upgrades to the fleet.

The brief

TfL tasked MARL with designing, manufacturing and installing a complete retrofit LED lighting system for its 72TS Bakerloo line fleet. We were asked to implement a bright, modern lighting system that reduced the fleet’s power usage.

Previously, the need for frequent maintenance work to repair the trains' faulty lights had caused service disruptions and delays. The brief emphasised the importance of producing a highly reliable system offering minimal downtime with reduced planned maintenance requirements.

The system was required to interface both mechanically and electrically with the existing systems on the trains to minimise retraining of staff.

The project

Before the design process could get underway, our engineering team had to inspect a rigorous set of rail performance and safety design standards. In total, we factored some 4,000 pages of standards, created between the early 20th century and the 1970s, into our complex V&V (Verification and Validation) design matrix.

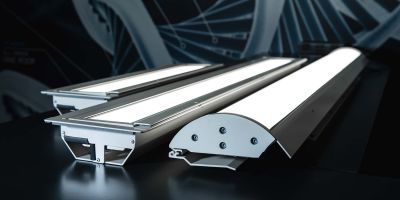

Next, we had to consider the limited space available, the need for the lighting system to be mechanically compatible with the existing lighting mounting points in all train locations and to offer the correct lighting levels both above and below ground. We designed a printed circuit board with patterned LEDs and onboard drive and control electronics to create a versatile modular system.

From our Ulverston factory, we manufactured nearly 5,000 lighting units which were shipped to London for installation.

The innovation

'Reliable' was the operative word throughout every phase of the design process. Our pursuit of guaranteed reliability led to the creation of an advanced energy storage system.

Electrified rail lines frequently suffer short gaps in electrification, causing temporary power losses which can cause disconcerting periods of blackout.

To improve reliability, MARL used an innovative electronic design to create a new energy storage system. It allows the entirety of the train’s interior lighting to operate without power in excess of three seconds. As a result, the lighting is now kept on whilst traversing over 90% of all electrification gaps on the Bakerloo line.

The result

Within 6 months of receiving the brief, we had designed a brand new LED lighting system that is now in operation across the Bakerloo line’s fleet of 36 trains and 252 carriages.

Ultimately, we responded to a complex brief with an elegant solution; a highly reliable, low-power modular lighting system built to last.

The fleets 4906 lighting units, comprising 512 power supply units, 1 million LEDs and more than 3 million components were all designed and manufactured at our Ulverston site. When lined up, the lighting units used as part of the project would cover the four-mile distance between Baker Street and Waterloo Station – the original length of the Bakerloo line!